Curls can be fabricated through kinds of types including roll forming stamping leaf bending and on a traditional press brake.

Curling process in sheet metal.

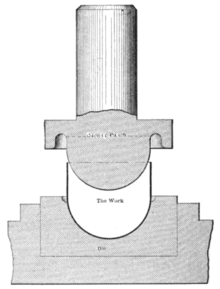

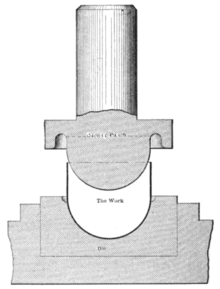

Curling is a sheet metal forming process used to form the edges into a hollow ring.

Door hinges are a good example of parts that are made using this process.

Other parts are curled to perform their primary function such as door hinges.

Curling on a panel or leaf bender is often limited to off center curls because most panel benders do not have tooling profiles which can create the necessary down bend to put the curl on center.

Curling is different than a tear drop hem because in a curl the edge finishes inside itself where a hem leaves the initial edge exposed.

Curling deforms metal into a tubular radial profile.

The curled edge provides strength to the edge and makes it safe for handling.

Metal curling operation in stainless steel shells ferrules with trimming beading machine.

Curling can be performed to eliminate sharp edges and increase the moment of inertia near the curled end.

Another common sheet metal forming process is bending.

Curling means forming an edge of circular cross section along a sheet or at the end of shell or tube.

This happens at the top and bottom surfaces since the bottom cutting die is pushing up with the same force that the punch is pushing down.

In manufacturing practice the plastic deformation occurring at the surfaces of the sheet metal at this stage in the cutting operation is referred to as rollover.

Curling is a sheet metal forming process that s used to smooth out the otherwise sharp and rugged edges of.

There is a difference between a curled edge and a tear shaped hem.

In curling the initial edge is rolled into the formed circle whereas in the tear shaped hem the initial edge is still exposed.

Curling also is used to smooth edges and add strength and rigidity to a part.

Curling is a sheet metal forming process used to form the edges into a hollow ring.

Curling can be performed to eliminate sharp edges and increase the moment of inertia near the curled end.

Sheet metal curling curling is the process of forming a circular ring at the edge of the metal sheet to make it safer for handling.

Other parts are curled to perform their primary function such as door hinges.