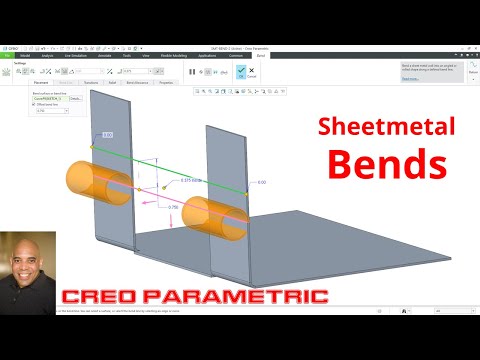

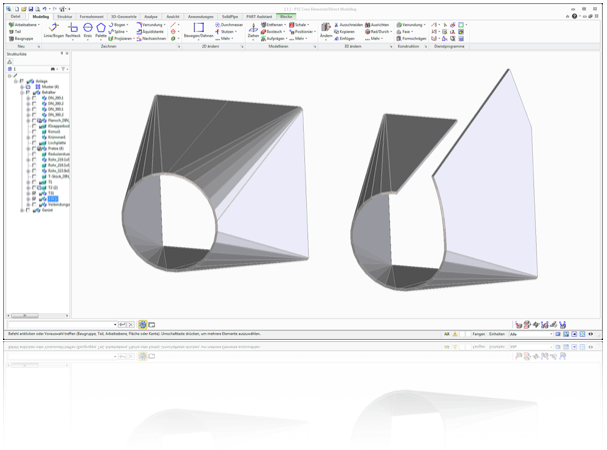

So what i did was build the extrude converted it to sheet metal driving surface and then added a bend feature selecting one of the end edges as the bend line the bend radius would be change from thickness to whatever diameter you are wrapping the label on to.

Creo sheet metal roll bend.

The parts you are making are not made with a press brake using a straight bend s.

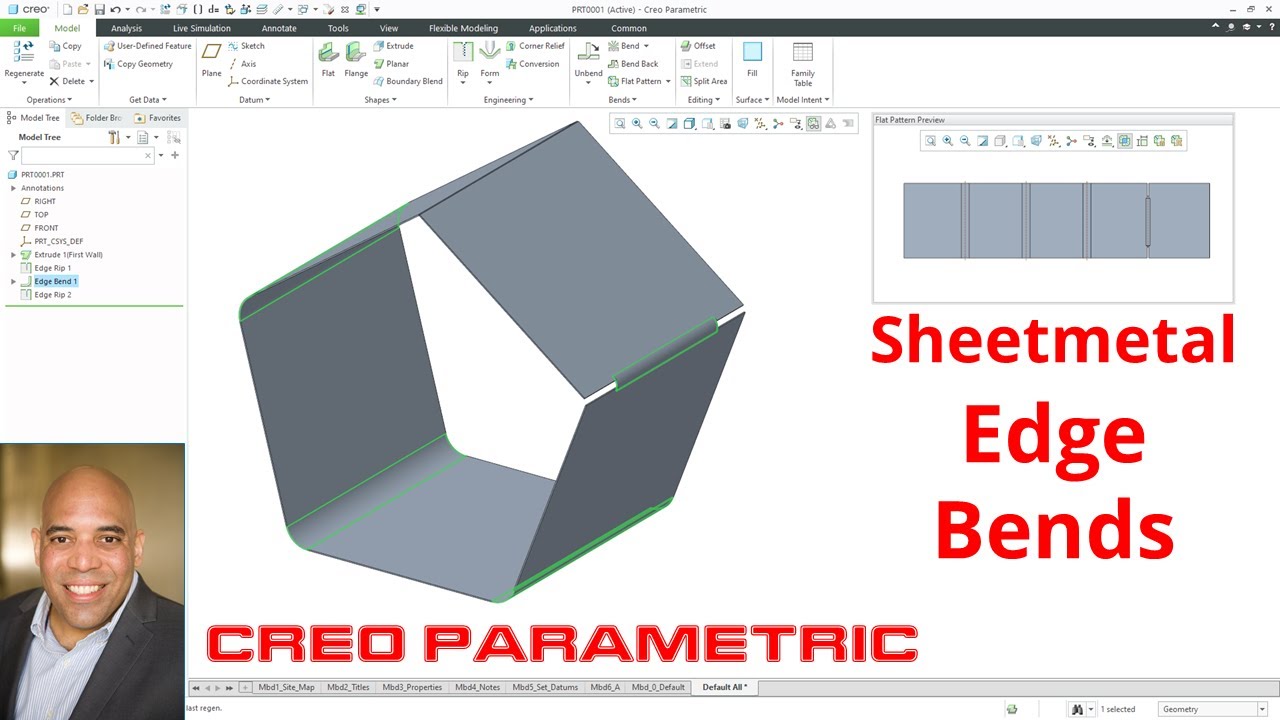

The split area splits the driving surface into two or more areas and you then add a bend to the surface you want to bend no need for an additional extrude to refill geometry.

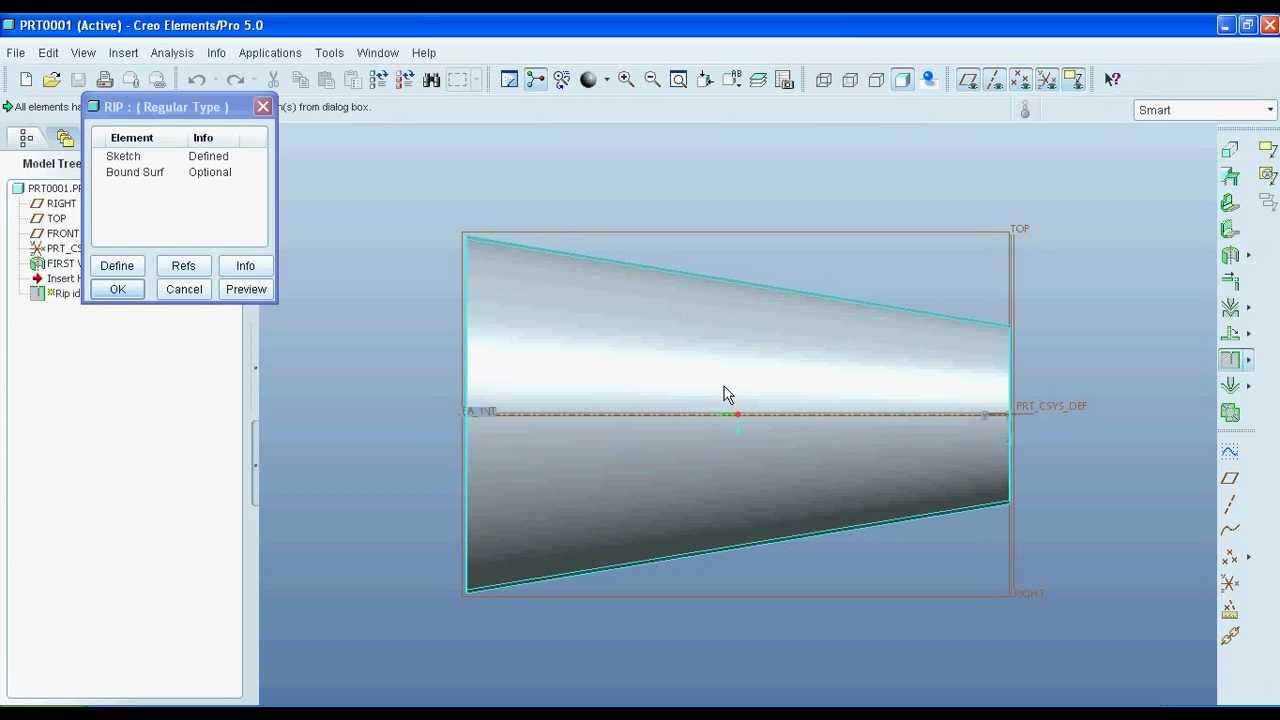

Exercise 21 sheet metal cylinders and linear patterns.

There are some methods you can use to roll your sheet but all of them have some problems you ll need to be aware of.

A toroidal bend will do a nice job of rolling the sheet but it won t keep rolling it back on itself like a spinal bend can.

Create internal sketch.

Click edit bendin the mini toolbar.

Now that you have a sheet metal part just go to the edit bendcommand.

Sheetmetal roll bend you can use sheet metal module to model these things but you can t generate a flat pattern using sheet metal.

Now you can use the draggers to change the angle or radius.

I don t know what you re actual geometry is but i m not sure we are talking about the same thing.

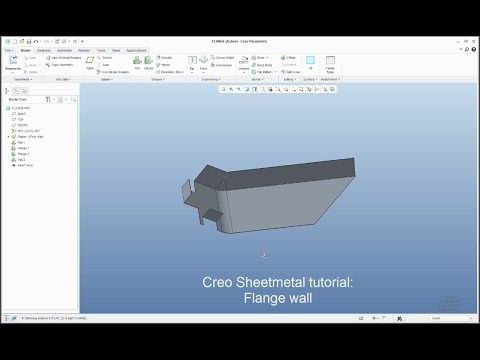

You will learn how to.

For this kind of thing i think a spinal bend is a better choice than a toroidal bend.